|

Our Experience

Power + Energy Associates is pleased to highlight their experience as consultants and advisors in thermal power investigations, studies, advisory work and performance testing. We have available on request a summary of selected assignments carried out since 1997. This experience is supported by more than 30 years continuous work in the field of thermal power plant performance. We are international and in addition to assignments carried out in the United Kingdom P+EA have worked directly in many countries and regions of the World including Australia, Bahrain, Bulgaria, Canada, China, France, India, Indonesia, Northern Ireland, Malaysia, Middle East, Pakistan, Philippines, Portugal, Sabah, Sri Lanka, Tunisia, United Arab Emirates and Thailand.

The experience of Power + Energy Associates includes having worked in 23 countries on more than 70 thermal power plants, 110 gas turbine units, 81 steam turbines, 41 CCGT plants, 67 conventional boilers, 76 HRSG units and 10 diesel power plants. These aggregate to 15000 MW thermal plant, 8100 MW gas turbine plant, 9500 MW CCGT plant, 17700 MW steam turbine capacity and overall 26000 MW power plant capacity.

A selection only of our experience summaries are provided here......................

Selected Experience 1997 - 2021

Investigation Studies

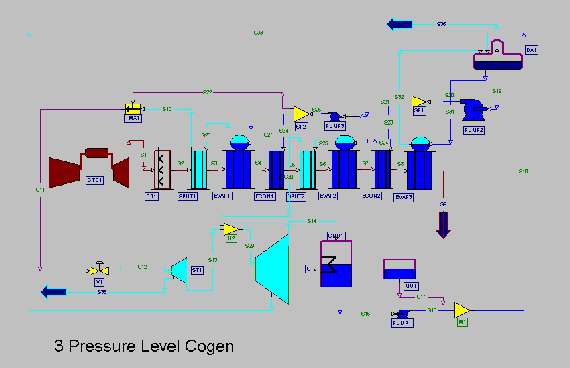

Investigation Study. Cogeneration Plant Performance – Thailand. Assigned to investigate and report on detailed plant performance and options for updating, re-configuring the existing 120MW Cogeneration plant. Created thermodynamic model of the plant with steam and gas turbine plant. Carried out analysis of design/ off-design performance and detailed thermodynamic cycle studies.

Investigation Study. Cogeneration Plant Performance – Thailand. Investigation and undertaking a detailed feasibility study for the export of steam to nearby industrial facilities included review of cycle performance and plant modification for existing 120MW Cogeneration plant.

Investigation Study. Gas Turbine Performance Degradation Investigation. Thailand. Making investigations and study of a 6FA gas turbine operational technical data and degradation trends over a two year period. Initiated by reported loss of output. Review of OEM reports. Ran Thermodynamic Model to assess performance changes and the gas turbine compressor deterioration. Advising on changes to plant air intake filtration. Follow up after the changes were implemented.

Investigation Study. Fujian Refining and Ethylene Project – China Assigned by International JV to investigate and review of the existing major refinery power plant facilities and options for importing steam from an adjacent utility power plant. The plant comprised gas turbines, steam turbines and conventional boilers requiring to be extensively modified to provide a new supply of steam and installation of a small steam turbine. Visits made to the plant. An assessment was made of the proposed modifications and their likely impact on station reliability, costs and economics. Thermodynamic modelling of the utility plant was carried out to assess changes to thermal efficiency.

Investigation Study. Operational Performance. Lignite / Biomass Fired Thermal Plant – Bulgaria. Investigation carried out over a two year period within a four year performance testing assignment. The plant comprised four conventional boiler - steam turbine units with a total 900 MW rating. Assigned as overall in charge of the investigation and testing at site involving a series of operational tests of the existing Russian steam turbine and boiler plant with a newly installed FGD plant. Attended and directly supervised operational performance benchmarking tests on site. The assignment included preparation of performance test procedures, all test preparations and arranging test instrumentation. The tests included plant output, heat rate, full and part load tests. Performance calculations carried out in accordance with DIN test codes.

Investigation Study. CCGT Gas Fired Plant – Tunisia. Engaged as independent performance engineer to investigate performance and prepare a detailed comprehensive computer model of the plant. The 500MW CCGT plant comprises gas turbines, steam turbine and boiler plant. The thermodynamic model replicates the plant thermodynamic performance and enabled the independent checking of OEM performance correction curves as well as the detailed assessment of performance including steam production, plant output, plant heat rate and fuel requirements under design and off-design operating conditions. Cycle analysis and review of the plant configuration and performance under both natural gas and fuel oil firing. By use of the model existing limitations on the OEM supplied data were remedied and performance data extended. Provided inputs and established curves needed for an automated Billing System for the plant.

Investigation Study. Turbine Reinstatement & Test Supervision. Industrial Cogen – India. Following major incident carried out Investigation, and monitored re-commissioning and re-testing of 50 MW Industrial Cogeneration Plant comprising Fluidised Bed Boiler, Waste Heat Recovery Boiler, and Steam Turbine Generator. Fluidised Bed Boiler fired by Pet Coke. Investigated boiler and turbine operational problems. Determined cause of failures. Was present on site for extended period investigating and directly monitoring the re-commissioning of the plant after repair to the steam turbine unit including re-balance. Re-tested the plant after start up. Provided a report, advice and monitoring of the post operational performance. Follow on assignment required monthly monitoring and review of operational performance data. Daily production reports reviewed and monthly report sent to Foreign Owners. Six monthly periodic site visits made to the plant over a three year period.

Selected Experience 1997 - 2021

CCGT Performance Assignments

Performance Assessment & Test Supervision. CCGT Cogeneration – Thailand. Natural Gas fired 120MW CCGT Cogeneration comprising two Gas Turbines and one Steam Turbine. Industrial CCGT (SPP) Project supplying Power and Steam to industrial estate. Assigned as the independent performance test engineer. Overall in charge of performance testing and supervision of tests on site. Assigned as Independent Performance Engineer to assess compliance of plant performance on behalf of the Owner. Supervised the Guarantee Performance Tests on behalf of Owner. Review of test instrumentation and calibration records. Contractor’s test reports reviewed, performance data was analysed and the Owner advised on acceptance of plant. Emissions monitoring. The outcome included resolving a performance shortfall due to contractor design shortcomings then retesting the plant proving compliance to performance obligations.

Performance Advisor. 120 MW Cogeneration Plant Gas + Steam Turbine Plant, Heat Recovery, Steam Generation – Thailand. Natural Gas fired CCGT Cogeneration plant comprising one Gas Turbine and one Steam Turbine. Providing technical support and advisory services for current and future performance of an existing Cogeneration plant. Three year Assignment. Created thermodynamic model of the plant and carried out analysis of design/ off-design performance. Carried out detailed cycle studies, review of test instruments and calibration records. Review of operational data. Reported on detailed study of the plant performance and options for updating/ re-configuring the cogeneration plant.

Performance Acceptance Testing 500 MW CCGT Gas and Steam Turbine Power Plant – Tunisia. Independent third party witness. Natural Gas and Oil fired CCGT comprising two Gas Turbines and one Steam Turbine. Independent Performance engineer for the construction of the plant. Providing performance advisory services. Review of all test related documentation submissions. Independent witness for performance testing and supervision of tests on site. Review of test instrumentation and calibration records. Attending and monitoring official performance tests, review of test data, analysing and reporting results. Includes effluent discharges and emissions. Reporting to the IPP Owners and advising on plant acceptance.

Performance Advisor and Annual Performance Testing 500 MW CCGT Gas and Steam Turbine Power Plant – Tunisia. Independent operational performance advisor. Natural Gas and Oil fired CCGT comprising two Gas Turbines and one Steam Turbine. Follow on assignment as Independent Performance Advisor ongoing since 2002. Post acceptance provided operational performance advisory services. Attending periodic tests. Advising and monitoring of the annual performance tests, review of data, analysing and reporting results including effluent / emission discharges. Created a detailed thermodynamic model of the plant and carried out analysis of design/ off-design performance. Ongoing providing periodic review of performance trends and degradation. Preparing reports on tests with trend analysis.

Thermodynamic Modelling and Performance Analysis 500MW CCGT Gas Fired Plant – Tunisia. Performance modelling. Natural Gas and Oil fired CCGT comprising two Gas Turbines and one Steam Turbine. Engaged as independent performance engineer to prepare a detailed and comprehensive computer model of the CCGT power plant. This model replicates the plant thermodynamic performance and enables the independent checking of OEM performance correction curves as well as the detailed assessment of performance including steam production, plant output, plant heat rate and fuel requirements under design and off-design operating conditions. Included thermodynamic and cycle analysis of the Facility including the review of the plant configuration and performance under natural gas and fuel oil firing. Using the model existing limitations on OEM data is remedied and performance data extended.

Performance Advisor and Updating of Performance Monitoring Systems for a 1000 MW Gas Fired CCGT Power Plant – United Kingdom. Independent operational performance advisor. Natural Gas fired CCGT comprising five Gas Turbines and two Steam Turbines. Assignment covered a 7 year period investigating, providing advice on operational performance and upgrading all performance monitoring systems. This CCGT comprises two CCGT Blocks each with gas and steam turbines. Review the test instrumentation and calibration records. Supervised and analysed tests on site. Prepared thermodynamic models of the plant. Carried out detailed cycle studies including extensive studies of plant component performance and historical data. Provided advice on upgrading all performance monitoring systems.

Refer also to experience listed under Cogeneration and conventional thermal plant performance.

Selected Experience 1997 - 2021

Expert Witness Assignments

Expert Witness - Fossil fired power plant combustion performance. Expert witness in an arbitration case in relation to a major fossil fuelled power plant. Assignment involved review of the entire combustion process, fuel handling systems, fuel preparation, fuel sampling and analyses, associated quality systems, review of operational data and performance analysis. Prepared an Expert Opinion and gave evidence in the Arbitration Court.

Expert Witness - Industrial Multi-fuel Watertube Boiler Design Review. Appointed as Independent Expert in relation to three Industrial Boilers covering various design matters and combustion performance. Carried out review of the project history and claims by the parties including contract interpretation and assessment of test results. Examined detailed design aspects including combustion performance. Working with the Client’s legal team. Prepared an Expert Opinion for presentation to the Court.

Expert Witness – Gas Fired Shell Boiler Combustion - United Kingdom Assigned as Expert Witness in relation to a failure investigation for a Gas Fired CHP/ Cogeneration Plant in UK. Carried out detailed investigations, devising and initiating a test programme to determine the cause of combustion related failures of gas-fired boilers. Provided report and technical evidence. Case settled out of court.

Dispute Resolution Board Member. Appointed as dispute resolution board member for a major CCGT project in the United Kingdom. Seven year assignment covering construction and initial five years operation period. Plant comprising gas turbines, steam turbines and boiler plant. Appointed jointly by owners and contractors. Board tasked with arbitration of technical disputes.

|